Aerogel: the counter attack road from "abandoned son" of architecture to "gold king" of industry

Under the wave of carbon neutrality, an underestimated nanomaterial is sparking an industrial revolution. Aerogel is creating amazing value in new energy vehicles, industrial pipelines, aerospace and other fields with its extreme heat insulation performance and ultra light characteristics. This article deeply analyzes how this "game changing" material breaks through cost constraints, constructs a market map worth billions, and reveals the technological breakthroughs and business logic behind its transition from laboratory to industrialization.

1、 Rebirth of the Jedi: Breakers in the Trillion Carbon Neutral Market

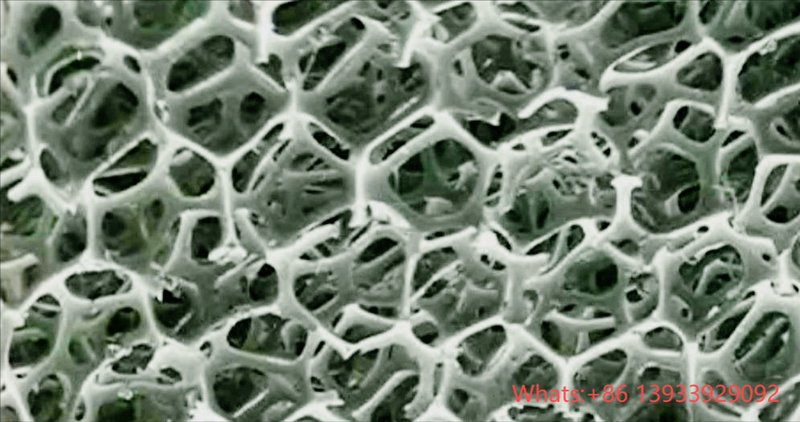

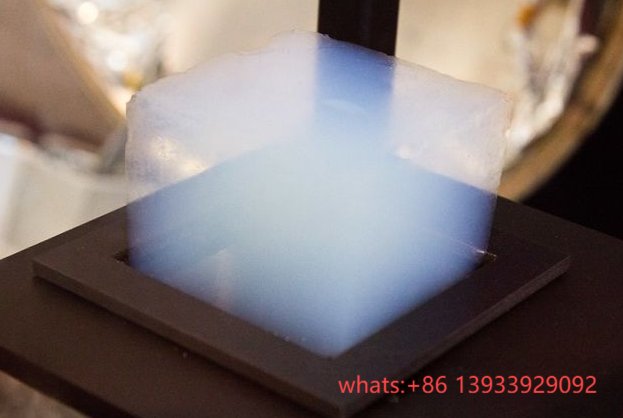

As the smallest density solid material in the world (as low as 3kg/m ³), aerogel has four subversive characteristics due to its nanoscale three-dimensional network structure:

Ultimate insulation: thermal conductivity as low as 0.013W/(m · K), lower than air

Ultra lightweight and strong: capable of bearing up to 4000 times its own weight

Fire and corrosion resistance: able to withstand high temperature flame impact at 650 ℃

Environmentally friendly: The main component is silica, which can be recycled and reused

These characteristics make it a strategic material for achieving carbon neutrality goals. The International Energy Agency predicts that the global industrial insulation market will reach 120 billion dollars by 2030, of which the permeability of aerogel is expected to exceed 15%.

2、 Technological Breakthrough: Cracking the 'Impossible Triangle' of Industrialization

The traditional aerogel industry is facing the dilemma of "high cost, low productivity and performance degradation". Through three major technological innovations, the industry is breaking through development bottlenecks:

Breakthrough direction of technological route, cost reduction, production capacity improvement, supercritical drying 2.0, solvent recovery rate increased to 95% 28% 3 times atmospheric pressure drying optimization, fiber reinforced composite technology breakthrough 41% 5 times new silicon source development, rice husk ash and other bio based raw materials replaced 33%-

Leading enterprises represented by Woqin Technology have compressed their production cycle from 72 hours to 8 hours through independently developed continuous production processes, with an annual production capacity of over 50000 cubic meters per line.

3、 Three major golden tracks ignite a market worth billions

1. New energy vehicles: the ultimate solution for battery safety

After Tesla Model Y adopts the aerogel fire blanket, the delay time of thermal runaway of the battery pack increases by 300%. The latest Kirin battery in Ningde era has integrated aerogel insulation layer, with energy density exceeding 255Wh/kg. Expected by 2025:

Bicycle usage: 0.8-1.2 square meters

Penetration rate: over 60%

Market size: Exceeding 8 billion yuan

2. Industrial pipelines: rewriting the century old insulation rules

In the application of Tahe Refining&Chemical, 15mm aerogel felt is used for DN500 steam pipeline instead of 50mm rock wool, which can save 3800 tons of standard coal annually. Industry calculation:

Oil and gas pipelines save maintenance costs of 72000 yuan per kilometer

Reduce steam pipeline heat loss by 40%

The market size is expected to reach 15 billion yuan by 2025

3. Aerospace: The 'Nano Armor' of Major Powers' Heavy Weapons

The Chinese space station uses aerogel composite plates to achieve extreme temperature difference protection between -120 ℃ and 1200 ℃. The Boeing 787 uses aerogel sound insulation layer to reduce cabin noise by 30 dB. The premium rate of products in this field exceeds 300%, making it a "value highland" in the civilian market.

4、 Cost Revolution: From Laboratory Treasures to Industrial Standard Equipment

Build competitive advantage through four major cost reduction paths:

Raw material innovation: The price of organic silicon monomer has been reduced from 50000 yuan/ton to 28000 yuan/ton

Technological breakthrough: domestication of supercritical equipment reduces investment costs by 60%

Recycling: Solvent recovery system reduces unit consumption by 35%

Scale effect: Unit cost reduction of 42% for enterprises with a production capacity of 100000 cubic meters

When the average market price drops to 800 yuan/m2, aerogel will achieve a subversive replacement in the field of building exterior walls. Taking 200mm concrete wall as an example:

Traditional solution: 80mm rock wool+plaster layer

Aerogel scheme: 10mm aerogel plate

- The comprehensive cost has decreased by 18%, and the occupancy rate has increased by 2.3%

5、 Industrial pattern: Chinese enterprises overtaking on the curve

It is worth noting that Chinese companies have formed 120 core patents in fields such as special fiber reinforcement and composite coating technology, including:

Super hydrophobic aerogel (contact angle>160 °)

Photocatalytic self-cleaning aerogel

Flexible foldable aerogel film

- Three innovative products lead the trend of next-generation technology.

CONTACT US

LATEST NEWS

Aerogel Clothing: How NASA’s Secret Weapon is Reinventing Winter Fashion

2025-03-10

Breakthrough Innovation: Resistant to extreme high temperatures of 1300 ℃! Woqin Technology Resolves the Industrial Protection Application of New Aerogel

2025-03-09

Aerogel: the counter attack road from "abandoned son" of architecture to "gold king" of industry

2025-03-08

Aerogel products and high-strength polyurethane cushion blocks: core materials of passive residential energy-saving revolution

2025-03-07

Study on flame retardancy of aerogel

2025-03-05