Breakthrough Innovation: Resistant to extreme high temperatures of 1300 ℃! Woqin Technology Resolves the Industrial Protection Application of New Aerogel

Hebei Woqin Trading Co., Ltd. focuses on cutting-edge material technology to interpret the thermal response from ceramic polymer aerogel (GT-mM-AZn) newly developed by Professor Zhao Haibo's team of Sichuan University. This material has an ultra-high compression modulus of 17.79 MPa and can be cut and processed at room temperature. Its compression strength is increased by nearly three times in a high temperature environment of 800 ℃. After being burned with a flame at 1300 ℃ for 60 minutes, the back temperature is only 30 ℃, and the flame retardant level reaches UL-94 V0. It provides extreme environmental thermal protection solutions for aerospace, new energy battery fire prevention, industrial kiln insulation and other fields. This article provides a detailed analysis of its dual network structure design, ceramicization reaction mechanism, and commercial application potential, helping enterprises achieve a dual upgrade of safety and performance. If you are interested in this type of innovative material, please feel free to contact Hebei Woqin Trading Co., Ltd.

1、 Industry pain points and technological breakthroughs

Traditional aerogels face two major problems:

Contradiction between mechanical properties and temperature resistance: inorganic aerogels (such as silica) are brittle, while organic aerogels (such as polyimide) are flammable and easy to collapse at high temperature12.

Insufficient adaptability to extreme environments: Structural failure under high temperature impact leads to a sudden drop in thermal insulation performance, posing a threat to personnel and equipment safety.

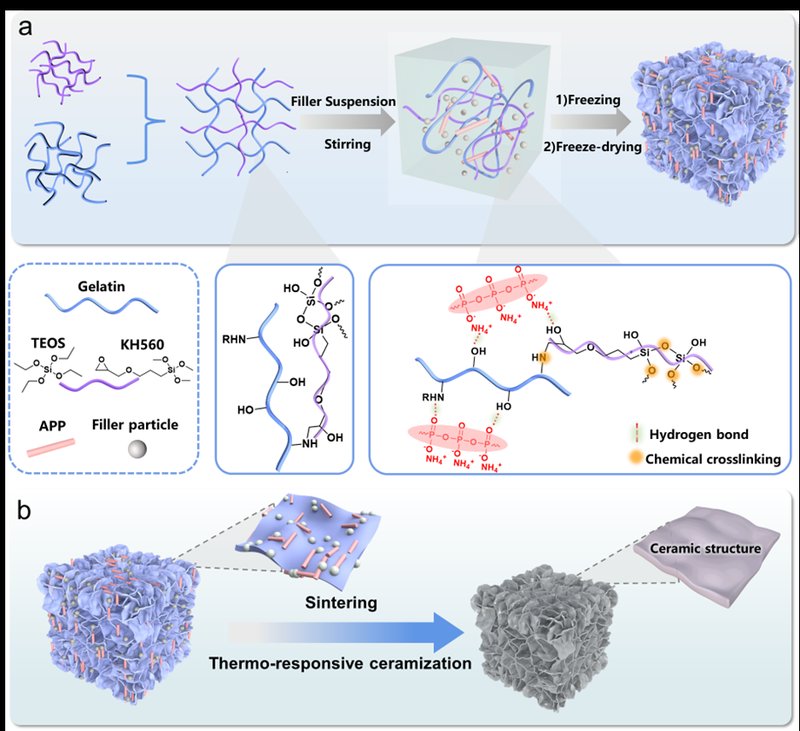

Professor Zhao Haibo's team developed GT-mM-AZn aerogel through the chemical physical double crosslinking network design, taking gelatin siloxane composite substrate as the core, introducing montmorillonite/mica ceramic filler and ammonium polyphosphate/zinc borate (APP/ZB) flux. The core breakthrough lies in:

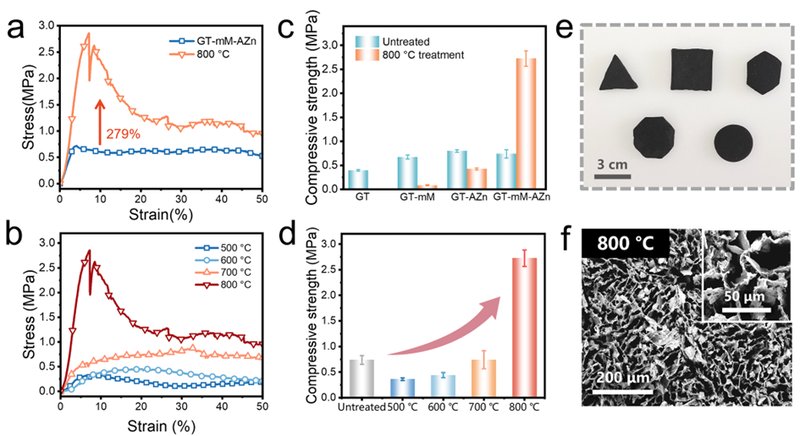

Performance at room temperature: Compressive modulus of 17.79 MPa, can withstand 50kg trampling with only 0.5mm deformation, supports secondary processing such as cutting and stamping.

High temperature strengthening: After being treated at 800 ℃ for 30 minutes, the compressive strength increased to 2.726 MPa (an increase of 268%), and the structural stability improved by 1.

- Ultra high temperature protection: The flame burns continuously at 1300 ℃ for 1 hour, and the temperature on the back remains stable below 300 ℃. The edge area is only 30 ℃, isolating 80% of the heat.

2、 Material preparation and core mechanism

1. Preparation process

Substrate construction: Gelatin provides flexible reinforcement, siloxane (TEOS/KH560) forms a rigid skeleton through hydrolysis condensation reaction, and epoxy groups crosslink with amino groups to strengthen the network.

Filler optimization: MMT/mica enhances high-temperature ceramic forming ability, APP/ZB flux promotes high-temperature molten phase generation, and liquid nitrogen freeze forming ensures uniform pore size.

2. Ceramic reaction mechanism

At high temperatures, the filler and substrate undergo multi-stage phase transitions:

400-600 ℃: APP/ZB decomposes into Zn ₂ P ₂ O ₇ and BPO ₄ glass phases, bonded with mica particles 12.

- Above 800 ℃: The siloxane skeleton is transformed into SiO ₂ ceramic, and the molten phase fills the pores, forming a dense eutectic structure and improving the thermal shock resistance by 18%.

3、 Performance advantages and measured data

Performance index test results Industry comparison limiting oxygen index (LOI)>60%, far higher than ordinary flame retardant materials (20-30%), vertical combustion grade UL-94 V0 (no droplets, self extinguishing time<10 seconds), higher than most engineering plastics (V1-V2), heat release rate (HRR) decreased by 58.3% compared with pure gelatin aerogel, significantly reducing fire diffusion risk, thermal conductivity<0.03 W/m · K (normal temperature), better than traditional rock wool (0.04 W/m · K)

4、 Commercial application scenarios

In the field of new energy, the fireproof isolation layer of lithium battery pack can suppress the spread of thermal runaway.

Heavy industry protection: lining steel and metallurgical kilns to reduce heat loss.

Aerospace: Rocket engine compartment insulation to resist ultra-high temperature airflow.

Building safety: Fireproof coating for high-rise buildings to enhance escape time windows.

5、 Value of cooperation with Woqin Technology

Hebei Woqin Trading Co., Ltd. relies on technology transformation from universities to provide:

Customized aerogel felt: support flexible adjustment of size, density and temperature resistance grade.

One stop solution: covering the entire process from material selection to installation guidance.

Cost optimization plan: Reduce unit price through large-scale production to help enterprises reduce costs and increase efficiency.

CONTACT US

LATEST NEWS

Aerogel Clothing: How NASA’s Secret Weapon is Reinventing Winter Fashion

2025-03-10

Breakthrough Innovation: Resistant to extreme high temperatures of 1300 ℃! Woqin Technology Resolves the Industrial Protection Application of New Aerogel

2025-03-09

Aerogel: the counter attack road from "abandoned son" of architecture to "gold king" of industry

2025-03-08

Aerogel products and high-strength polyurethane cushion blocks: core materials of passive residential energy-saving revolution

2025-03-07

Study on flame retardancy of aerogel

2025-03-05