Application and advantages of aerogel in architecture

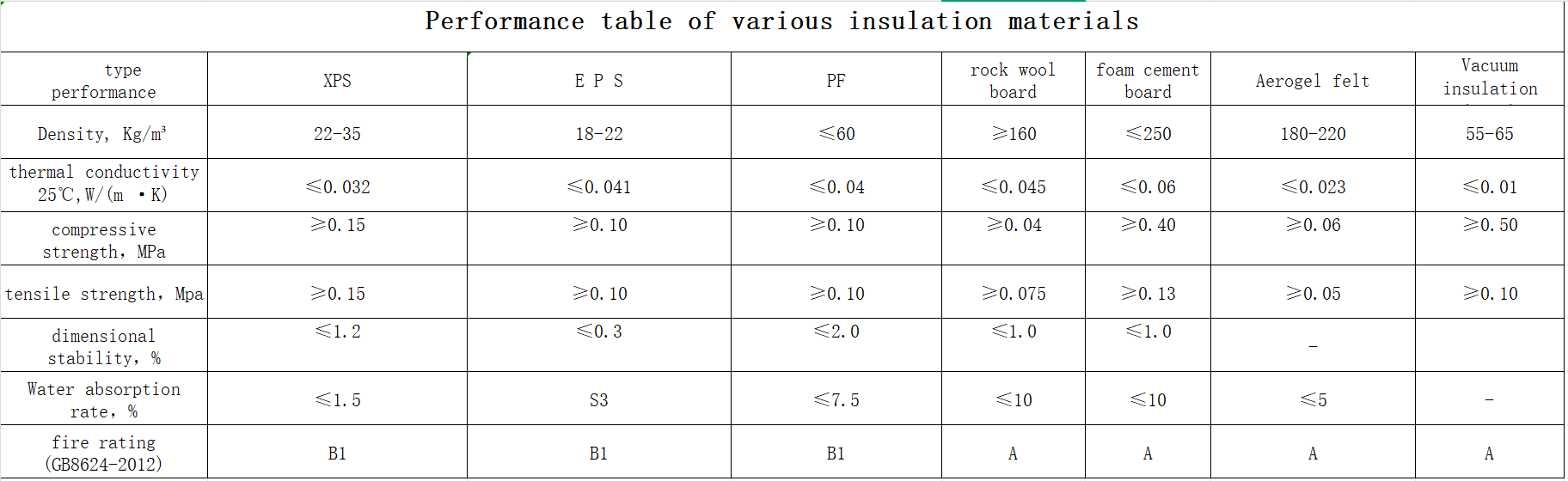

At present, the thermal insulation materials commonly used for building exterior walls are mainly organic polymer porous foam materials, inorganic fiber cotton and foam inorganic thermal insulation materials. Organic polymers such as extruded polystyrene board and graphite polystyrene board occupy the vast majority of the market share due to their excellent insulation effect, lighter material density, and convenient construction operation. However, flammability is their fatal disadvantage. There have been frequent cases of fires in building exterior wall insulation materials, causing serious losses to personnel and property. Various regions have also introduced restrictions on the application of flame retardant grades for exterior wall insulation materials. Inorganic insulation materials such as perlite board have better combustion performance than organic insulation materials, but their thermal conductivity and bulk density are slightly inferior, which cannot meet the market's requirements for ultra-low energy building insulation materials. SiO2 aerogel, as a multi-functional high-efficiency thermal insulation and environmental protection material, has been used for many years in the fields of aerospace, petrochemical, and building insulation due to its unique characteristics of low thermal conductivity, high temperature resistance, and non combustible in case of fire.

As a new type of high-efficiency thermal insulation material, aerogel felt has the following significant advantages when applied to building thermal insulation:

▶️ Super thermal insulation performance (aerogel thermal insulation material, thermal conductivity 0.018W/m · K)

Composite structure: 3-20mm aerogel glass fiber mat+glass fiber needle felt

Thermal resistance efficiency: 50% thinner than traditional materials, increasing building plot ratio by 3-5%

Physical parameters: density 180-220kg/m ³, thermal conductivity at 25 ℃ 0.018W/(m · K)

▶️ Excellent hydrophobicity (hydrophobicity rate of 99.7%)

Comparative analysis: rock wool hydrophobic agent fails within 3 years, and the hydrophobic rate of aerogel felt remains 99.7% throughout its life cycle

Moisture proof certification: Passed ASTM C1104 water vapor penetration test

▶️ A1 level fire protection system (A-level fireproof material, temperature resistance of 600 ℃)

Fire Protection Verification: Passed GB 8624-2012 Combustion Performance A1 Level Certification

Safety features: No open flames/droplets generated, flame propagation speed reduced by 80%

▶️ Long term lifecycle (reducing building maintenance costs)

Service life:>25 years (traditional materials 5-8 years)

Maintenance cost: 60% reduction in full cycle maintenance expenses

▶️ Green construction characteristics

Installation efficiency: Trimmability improves construction speed by 40%

Environmental certification: Passed LEED v4.1 material cycling assessment

▶️ Multi functional added value

Sound insulation performance: noise reduction coefficient of 0.85 in the 125-4000Hz frequency band

Seismic performance: elastic modulus>1.2MPa (JG/T 536-2017)

In addition, aerogel can also improve the sound insulation effect of buildings, help to reduce noise pollution and improve living comfort; In addition, the service life of aerogel is more than 5 times that of traditional materials, which can provide good thermal insulation effect for a long time and reduce the maintenance cost of later buildings. It is an excellent building thermal insulation material. As a new green building material, aerogel is applied to buildings in various forms such as coating and composite plate, which can improve the overall thermal insulation and energy saving effect of building structures, facilitate construction, reduce fire hazards, and provide more protection for personal and property safety.

1. Vacuum insulation board, thermal conductivity 0.008W/(m · K)

The board is an efficient insulation board made of inorganic fiber core material and high resistance gas composite film through vacuum sealing technology. The thermal conductivity of air is approximately 0.023W/(m · K), and to achieve a lower thermal conductivity than air, only vacuum can be used.

Its biggest advantage is its insulation performance, which can surpass all other types of insulation materials. Hidden danger issues, such as the difficulty in maintaining vacuum degree that everyone will raise: if damage occurs, the insulation performance of the board will plummet; Secondly, the existing construction technology leads to too many board joints and thermal bridges, which poses a high risk of condensation; Furthermore, the smoothness of construction is also difficult to control.

2. Aerogel thermal insulation material, thermal conductivity 0.02W/(m · K)

Aerogel material is called the lightest solid in the world. It has superior properties such as high temperature resistance, low thermal conductivity, low density, high strength, green environmental protection, waterproof and non combustible, while also possessing superior sound insulation and shock absorption performance. It is an indispensable high-efficiency insulation material in metallurgy, chemical industry, national defense, aerospace and other fields.

The aerogel composite thermal insulation material is made by combining silica aerogel with the base material through a special process, which overcomes the brittleness of the aerogel itself. For example, the aerogel glass fiber felt has obvious advantages in thermal insulation.

3. Polyurethane foam material, thermal conductivity 0.024W/(m · K)

Divided into on-site foamed polyurethane and factory prefabricated rigid foam polyurethane boards. On site foamed polyurethane has excellent integrity and waterproofness, making it very suitable for roof insulation and waterproofing, as well as insulation and waterproofing inside basement walls. It is applied for insulation inside dry hanging curtain walls, with convenient construction operations and maximum prevention of thermal bridging. Most polyurethane materials are grade B1 and B2, and a small portion of composite polyurethane boards can reach grade A.

4. Extruded polystyrene board, thermal conductivity 0.030W/(m · K)

Extruded polystyrene board is also a type of polystyrene board, but the production process is extrusion molding. Extruded polystyrene board, referred to as XPS board, is a rigid foam plastic product with closed cell structure made by heating extrusion molding with polystyrene resin or its copolymer as the main component and a small amount of additives.

5. Inorganic polymer insulation board, thermal conductivity 0.030W/(m · K)

It is an inorganic foam material that is surrounded by a film of strong and tough calcium carbonate using polyvinyl chloride resin, creating an extremely well insulated and sealed space. It will not burn or melt under flames. Under prolonged flames, a small portion of the material forms carbonization and maintains its original shape, making it an A-grade fire-resistant material.

Excellent insulation performance, fire resistance, and low water absorption, but without price advantage.

6. Phenolic board, thermal conductivity 0.032W/(m · K)

It is a porous phenolic foam board made from the condensation polymer of phenol and formaldehyde (phenolic resin) and other additives such as curing agent, foaming agent, surfactant and filler. Phenolic panels produced abroad have good insulation performance, with lower thermal conductivity than extruded polystyrene panels. Phenolic panels are widely used in sandwich insulation systems in Japan.

7. Graphite polystyrene board, thermal conductivity 0.033W/(m · K)

Graphite polystyrene board is a type of expanded polystyrene board, a classic product of chemical giant BASF. It adds infrared reflector to polystyrene raw material, which can reflect thermal radiation and improve the insulation performance of EPS by 30%. At the same time, its fire resistance can easily achieve a leap from B2 to B1 level.

The most cost-effective insulation product, widely used and with a large market value.

8. Rubber insulation material, thermal conductivity 0.035-0.04W/(m · K)

Flexible foam rubber and plastic thermal insulation products can be defined as flexible thermal insulation products with closed cell structure processed by mixing, extruding, foaming, cooling and shaping with natural or synthetic rubber and other organic polymer materials as the base material, adding various additives such as aging agents, flame retardants, stabilizers, vulcanizing accelerators, etc.

9. Real gold plate, thermal conductivity 0.036W/(m · K)

The gold plate belongs to the modified polyphenyl plate, which is processed by the internationally advanced phase change wrapped thermal insulation and energy storage technology and has a continuous honeycomb structure of heat break and barrier. After modification, the fire resistance reaches A2, so the foam particles themselves will not burn. As shown in the picture, it is a popular genuine gold board, but it is not a truly fire-resistant A-grade material. 10. Expanded polystyrene board with thermal conductivity of 0.039W/(m · K) is a polystyrene foamed plastic board with closed cell structure, which is made from expandable polystyrene beads that are heated, pre foamed and heated in a mold. Mature and widely applied, commonly used in thin plastering systems, integrated insulation and decoration systems, large mold embedded systems, steel wire mesh panel systems, etc.

11. Rock wool board, thermal conductivity of 0.04W/(m · K)

A hydrophobic insulation board made from natural rocks as the main raw material, melted at high temperature, and blown by centrifugal injection. It is pressed and cut after adding a certain proportion of binders and additives.

Rock wool board is a material with high water absorption. In hot summers and cold winters in China, due to heavy rainfall and high air humidity during the rainy season, the insulation system of rock wool board may become damp and reduce its insulation performance. For areas with less rainfall in the north, rock wool board is an external insulation material with good fire resistance.

12. Inorganic fiber spray insulation material with a thermal conductivity of 0.04W/(m · K)

Inorganic fiber spraying materials are mainly composed of inorganic fibers and water-based adhesives. After mixing, they are sprayed by an air pressure pump and mixed with atomized water to form a coating on the substrate that needs to be protected. This coating can meet the requirements of sound absorption, insulation, and fire protection. This material is lightweight, non-toxic and odorless, with good sound absorption, weather resistance, efficient insulation, reliable fire resistance, and can achieve high fire resistance protection for more than 5 hours. However, it is difficult to achieve both tensile strength and thermal insulation performance.

13. Gas condensate, thermal conductivity 0.04W/(m · K)

Gas reinforced concrete is also a product system for on-site spraying construction. Its main component is magnesium oxide (MgO), an ideal high-temperature refractory material. The product does not contain any organic substances, and it not only does not release any harmful gases, but also can adsorb carbon dioxide in the air, reducing the greenhouse effect of the atmosphere and regulating the environment.

It is a white foam like material, similar to the construction process of polyurethane. However, polyurethane solidifies rapidly during spraying, while aerogel can flow. It is beneficial for the construction of dry hanging curtain wall buildings, but the strength is not strong and there is a risk of water absorption.

14. Glass wool board, thermal conductivity 0.042W/(m · K)

Glass wool is a material that transforms molten glass into a cotton like structure. It belongs to the glass category and is an inorganic fiber with good formability, low bulk density, high thermal conductivity, thermal insulation, good sound absorption performance, corrosion resistance, and stable chemical properties. Glass wool board is a plate-shaped product with a certain degree of rigidity made by applying thermosetting adhesive to glass wool. Rock wool products are mainly made of exquisite basalt, while glass wool is mainly made of glass

15. Composite magnesium aluminum silicate insulation material with a thermal conductivity of 0.045W/(m · K)

Composite magnesium aluminum silicate insulation material is mainly made of inorganic materials such as palygorskite, sepiolite, bentonite, ceramic fibers, etc. On the basis of the original magnesium silicate insulation material, harmful substances such as rock wool are removed, and various special composite materials are added. It is refined through scientific formula and advanced technology, and has the advantages of non flammability, environmental protection, and long service life.

16. HX isolated insulation board, thermal conductivity 0.045W/(m · K)

It is a composite fireproof insulation board mainly made of EPS polystyrene board, adopting special structural forms and process measures, and embedding high-efficiency fireproof agents into EPS board.

This material involves slotting EPS, then filling it with mortar, and finally coating the outer surface with mortar. After fire testing, it meets the A-level non combustible standard. The production process has become more complex compared to EPS, and the cost has also increased. In theory, the risk of surface cracking is extremely high when organic and inorganic materials are interlocked to fill the joints.

17. Foam glass insulation board, thermal conductivity 0.045W/(m · K)

It is a material mainly made of quartz sand powder or glass powder, with additives such as foaming agents and accelerators added. It is finely ground and uniformly mixed to form a compound, which is melted, foamed, and annealed to form a material filled with uniformly closed pores inside. The foam glass insulation board is a closed cell foam glass insulation product. Compared with rock wool, foam glass does not absorb water, so it has a good advantage on the roof, but the price is high.

18. Polystyrene particle insulation mortar, thermal conductivity 0.058W/(m · K)

Polystyrene particles are expanded polystyrene foam particles or polystyrene particles, which are expanded and foamed with expandable polystyrene resin as the basic raw material. Polystyrene particle insulation mortar is a slurry composed of mortar and polystyrene particles, with a polystyrene particle content of not less than 80%.

The insulation performance is slightly poor and not suitable for building external insulation projects that require high energy efficiency. The water absorption rate is also relatively high. Thermal insulation mortar materials have a characteristic that their comprehensive performance varies with material blending, and they are not a stable material system.

19. Fiber reinforced composite insulation board, thermal conductivity 0.065W/(m · K)

The main raw materials for fiber-reinforced composite insulation boards are flame-retardant foam materials, binders, and various modifiers. They are produced using advanced production processes and scientific ratios, and are formed by one-time pressing on assembly lines, followed by steam curing and natural curing. Also known as silicon rock slab, it is called Jinbang slab in Shanghai.

Good fire resistance, high strength, not easily broken, but average insulation effect.

20. Foam cement board, thermal conductivity 0.065-0.070W/(m · K)

Closed cell lightweight foam cement board, also known as composite foam cement board, is made from cement, fly ash, silica fume and other main raw materials through processes such as foaming, curing, and cutting. This is a relatively pure type of inorganic insulation board. The threshold is too low, competition is fierce, product quality cannot be guaranteed, and insulation performance is poor.

21. Inorganic insulation mortar prefabricated board, thermal conductivity coefficient 0.065-0.070W/(m · K)

Taking expanded vitrified microbead insulation mortar as an example, it is a premix made by mixing expanded vitrified microbeads, inorganic cementitious materials, additives, fillers, etc. If the prefabricated production of panels is carried out in the factory, it is the plate-shaped insulation material referred to in this title. The main material, expanded vitrified microbeads, is an inorganic particle material made from glassy volcanic lava sand through processes such as expansion and vitrification. The surface is vitrified and closed, forming an irregular spherical shape, while the interior has a porous cavity structure.

Inorganic insulation mortar is a material system with relatively poor insulation performance, but factory prefabricated insulation boards have more reliable quality in terms of insulation performance.

Other... Of course, basically all insulation systems have different defects. In the field of building energy conservation, bold innovation and experimentation have made vacuum insulation board external insulation systems one of the important solutions for building exterior walls in some parts of China, and even applied in passive low-energy buildings in northern China.

There is no perfect insulation material in the world. However, the material itself may not necessarily affect the final quality of the product. The above materials all have their own advantages, which are not possessed by other materials. But no matter how good the product is, it's useless without good manufacturers and workers to make it well. One point for product, two points for design, and seven points for construction have always been the default quality formation factors in the construction industry. Woqin is able to explore and innovate, develop advanced and suitable new products, and ensure quality as much as possible in terms of construction level.

CONTACT US

LATEST NEWS

Ultra density rigid polyurethane insulation block: high-strength invisible guardian in the construction industry - decryption of 600kg/m ³ industrial revolution new materials

2025-03-14

Aerogels: a comprehensive analysis from nanostructures to future science and technology - classification, innovation and application revolution

2025-03-14

Aerogel Clothing: How NASA’s Secret Weapon is Reinventing Winter Fashion

2025-03-10

Breakthrough Innovation: Resistant to extreme high temperatures of 1300 ℃! Woqin Technology Resolves the Industrial Protection Application of New Aerogel

2025-03-09

Aerogel: the counter attack road from "abandoned son" of architecture to "gold king" of industry

2025-03-08