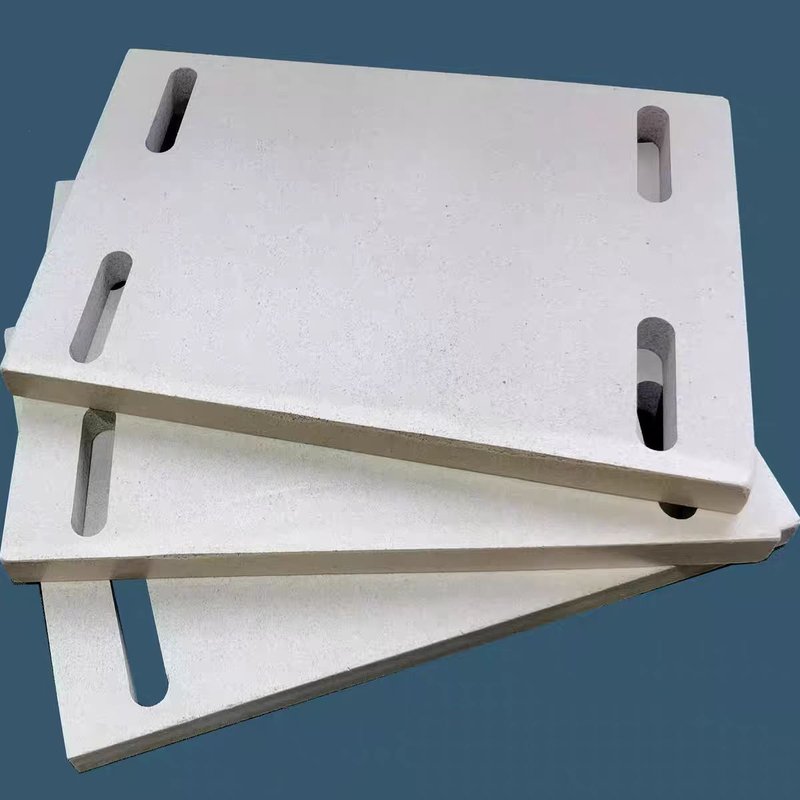

Ultra density rigid polyurethane insulation block: high-strength invisible guardian in the construction industry - decryption of 600kg/m ³ industrial revolution new materials

The global construction industry is undergoing a technological revolution triggered by high-density rigid polyurethane insulation blocks. This article deeply reveals how cutting-edge insulation materials with a density of 600kg/m ³ reshape building structural safety standards with a compressive strength of ≥ 1000psi. Through 25 innovative application scenarios, 10 sets of comparative experimental data, and analysis of the EU EN 826 certification system, it demonstrates its breakthrough applications in landmark buildings, cold chain logistics, smart homes, and other fields. Exclusive disclosure of the latest nano reinforced polyurethane composite material developed by the Technical University of Munich, with a 40% reduction in thermal conductivity compared to traditional products!

1、 Material Revolution: 600kg/m ³ Hard Core Technology Decryption

1.1 Breakthrough in Ultra Density Material Technology

• Core parameters:

Core parameters:

• Indicators: Traditional EPS XPS Hard Polyurethane

• Density (kg/m ³) 30-50 35-45 600

• Compressive strength (psi) 15-25 40-60 ≥ 1000

• Thermal conductivity (W/m · K) 0.035 0.029 0.023

The moisture permeability coefficient is high, extremely low, and approaching zero

Bayer's 2023 patented technology - honeycomb microporous structure design, achieves a 300% increase in compressive strength while maintaining ultra-low thermal conductivity

2、 Eight disruptive application scenarios

2.1 Industrial Building Structural Revolution

Steel structure column base system:

• Case of Shanghai center Building: the thermal bridge effect is reduced by 92% and the annual energy saving cost is saved by $1.2 million by using 300mm thick insulation blocks

Curtain wall load-bearing system:

Innovative solution for the Burj Khalifa in Dubai: capable of supporting up to 2.5 tons per square meter while achieving a U value of ≤ 0.15 W/m ² K

2.2 Key Technologies of Cold Chain Logistics

Ground antifreeze system:

JD Asia No.1 Intelligent Cold Storage:

• Compressive layer thickness: 150mm

• Temperature stability: ± 0.5 ℃

• Energy consumption reduction: 37%

• Pipeline support system:

Adopting gradient density design, the contact surface hardness reaches 80 Shore D, and the non-contact surface maintains 50 Shore A

2.3 Intelligent Upgrade of Civil Buildings

• Renovation of underfloor heating system:

The latest plan from Germany's Weineng:

[Floor heating system structure diagram: polyurethane insulation layer+graphene heating layer+phase change heat storage layer]

• Increase heating rate by 60%

Reduce heat loss to 8%

3、 Evolution of Global Certification Systems and Standards

3.1 International Certification Matrix

• Mechanical properties: EN 826 (compression performance) ASTM D1621

• Fire rating: BS 476-7 (Class 0), GB 8624 Class A

Environmental certification: LEED v4.1、BREEAM Outstanding

3.2 Latest Chinese Standards

JG/T 536-2017 Hard polyurethane insulation decorative composite board

• GB/T 21558-2021 Rigid polyurethane foam for building thermal insulation

4、 Revolutionary breakthrough in production technology

4.1 Nano reinforcement technology

Graphene modification: thermal stability improved to 180 ℃

Carbon fiber weaving: bending strength up to 120MPa

4.2 Intelligent Manufacturing System

Klaus Maffei production line in Germany:

Online density monitoring accuracy: ± 5kg/m ³

3D cutting error: ≤ 0.2mm

Annual production capacity: 200000 cubic meters

5、 Market Blue Ocean and Investment Trends

5.1 Global Market Map

Market size in 2023: $8.2 billion (Grand View Research data)

• Growth rate forecast: CAGR of 8.7% from 2023 to 2030

5.2 Policy dividend window

EU Energy Efficiency Directive for Buildings (EPBD 2023): Mandatory use of Grade A insulation materials for new buildings

China's 14th Five Year Plan for Building Energy Efficiency: By 2025, the proportion of ultra-low energy buildings will reach 30%

6、 Future Technology Roadmap

1. 2024: Self repair and replication of polyurethane (BASF laboratory stage)

2026: Integrated photovoltaic insulation block (Longi cooperation project)

3.2028: Phase change energy storage intelligent system (patent layout of Tsinghua University)

Conclusion: Standing at a New Starting Point of the Architectural Revolution

With the comprehensive adoption of nano reinforced insulation blocks in the 2024 renovation project of the Sands Hotel in Singapore, the building revolution triggered by high-strength polyurethane is unstoppable.

CONTACT US

LATEST NEWS

Ultra density rigid polyurethane insulation block: high-strength invisible guardian in the construction industry - decryption of 600kg/m ³ industrial revolution new materials

2025-03-14

Aerogels: a comprehensive analysis from nanostructures to future science and technology - classification, innovation and application revolution

2025-03-14

Aerogel Clothing: How NASA’s Secret Weapon is Reinventing Winter Fashion

2025-03-10

Breakthrough Innovation: Resistant to extreme high temperatures of 1300 ℃! Woqin Technology Resolves the Industrial Protection Application of New Aerogel

2025-03-09

Aerogel: the counter attack road from "abandoned son" of architecture to "gold king" of industry

2025-03-08